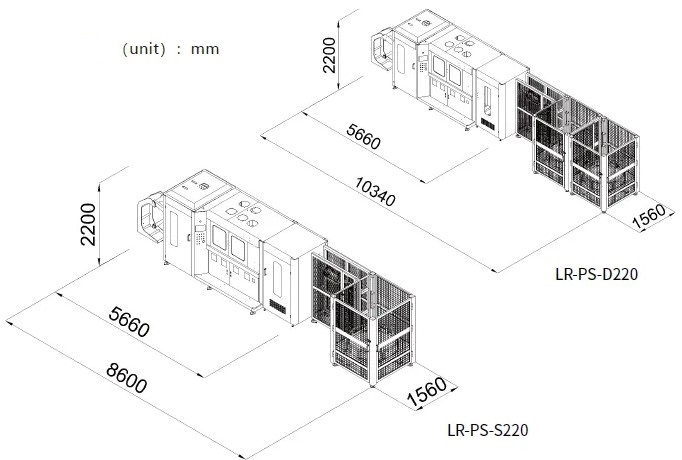

LR-PS-S(D)220

Manufacture quickly and reliably through continuous quality testing and with proof of quality!

Production capacity of 220 springs per minute

– Extra high speed: 220 springs/min, the highest in the industry.

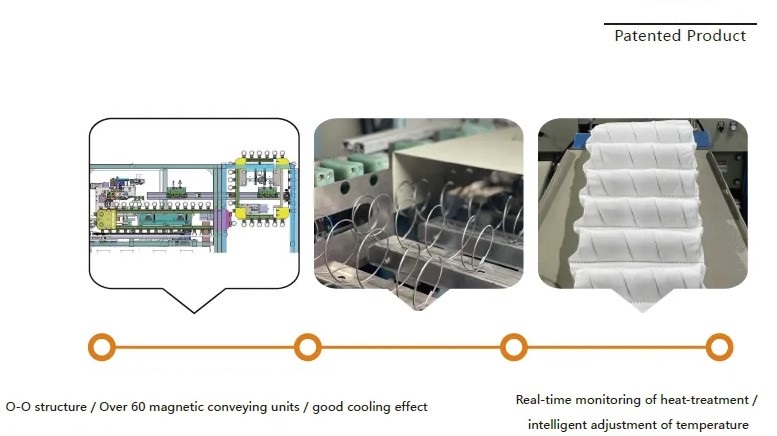

– The patented Double-O-Loop spring belt with more than 60 magnetic holders, resulting in a longer cooling time during heat treatment

– Heat treatment first, then extrusion.Real-time monitoring of heat treatment.

– Ultrasonic welding technology:Stable and efficient welding process, resulting in good welding quality.

– Intelligent temperature adjustment

Adhesive tank capacity: 8 kg

Air consumption: approx. 0.35 m³ / min.

Air pressure: 0.6 – 0.7 MPa

Power consumption: approx. 8 kW + 42 kW

Volt: 3AC 380V

Frequency: 50 or 60 Hertz

Input current: 15A + 70A

Cable cross sections: 3 * 10 mm² + 2 * 6 mm² and 3 * 16 mm² + 2 * 10 mm²

Working temperature range: + 5 ° C – + 45 ° C

Weight: approx. 7000 kg

Option 1

– Wire 1.6 – 2.3 mm

– Spring diameter 48 – 75 mm

– Spring height 80 – 250 mm

Option 2

– Wire 1.6 – 2.1 mm

– Spring diameter 38 – 65 mm

– Spring height 60 – 220 mm

Non-Woven

Weight: 65 – 90g / m²

Width: 220 – 600 mm

Roll diameter (inside): min. 75 mm

Roll diameter (outside): max. 1000 mm

Spring wire

Wire diameter: 1.4 – 2.1 mm

Diameter of crown stock (inside): min. 320 mm

Diameter of crown stock (outside): max. 1000 mm

Capacity of the wire reel: max. 1000 kg

Glue

Composition: from pellets or pieces

Viscosity: 125 ° C – 6100 cps; 150 ° C – 2300 cps; 175 ° C – 1100 cps

Melting point: 85 +/- 5 ° C